How Does Printing Work

How does printing work? Printing has been among the most critical processes in knowledge preservation throughout history. Now, it plays an important role in many businesses, including corporations, schools, and other fields as well. Printing involves many different kinds of processes and different types of machines. The machines used nowadays are far more digitalized compared to traditional ones which people used centuries ago. This article will tell you about the basis of printing and how it actually works.

What is Printing?

Printing is when an object that includes ink transfers onto the desired material you want. The main object of any printing machine is the printing plate, which is covered in ink as is then pressed against any type of material. The older version of printing, which included the printing press, required a lot of manpower and effort. Now, however, you have numerous printing options, such as laser and inject printing. Both these machines produce significant outputs compared to the printing press; this is of course, after all the inventions and upgrades that were made by people.

Steps of Printing Process

Mentioned below is the summary of the three main standardized steps which each printing process carries out:

- Prepress: This is when the image transfers onto the inked plate. In this step, operations such as typesetting, image preparation, graphic arts, and the placing of the image takes place.

- Press: This step involves the actual printing process in which you receive the printed image.

- Postpress: This step refers to the finishing touches that take place on the printed image. Final touches mostly include the process of binding.

Direct vs. Indirect Printing

There are almost five types of the printing process, and these come under two headings:

Direct Printing

Direct printing is when the print image transfers on to the preferred material. This type of printing includes screen printing, flexography, gravure, and letterpress printing processes.

Indirect Printing

Indirect printing uses an additional technique that helps to form a good quality print. This technique involves an engraved inked plate which presses onto the surface of the material such as paper or cloth.

What Chemicals are involved?

There are three main types of chemicals used in each operation of the printing process.

- Photo processing Chemicals: You use these chemicals in the prepress step of the printing process

- Ink and Cleaning Solvents. These are the major types of chemicals which are useable during the main step of the printing, which involves the press

- Adhesives: You can use adhesives during the post-press of the printing process. It is advisable to use this if you’re printing out books.

Types of Printers

Mentioned below are the three main types of printers and how each printer works to help you get the printable image:

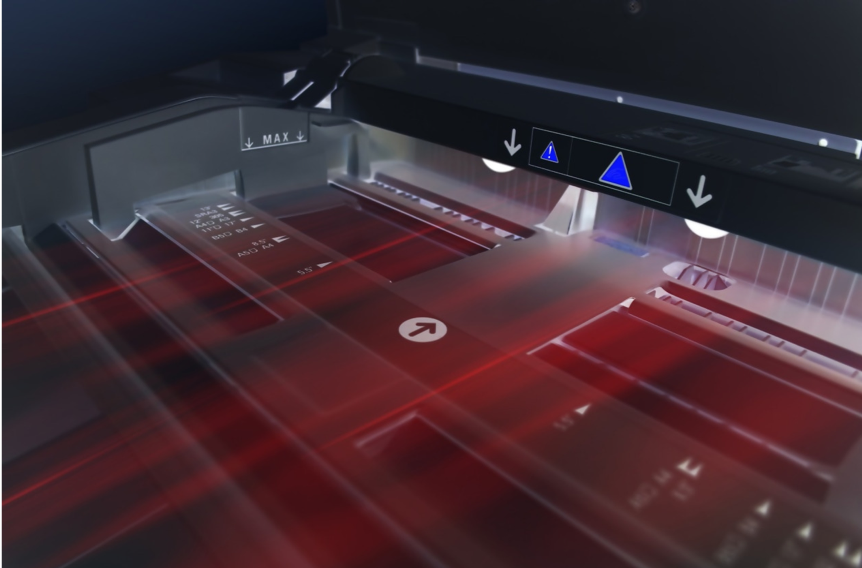

1. Laser/LED Printers

These printers are very common in the printing industry, especially in today’s generation. This type of printer helps you to get prints of high color quality and are also much more efficient compared to the printing press. These printers use the exposure of light to print out images, it can be very tricky on how these printers work, but it’s not very difficult for you to understand. Laser printing machines use toners that shine on to the drum. The paper moves towards the drum, which enables the image to be printed out on the paper. Finally, the paper passes through a heated roller, which helps to melt the particles of the toner in order for it to stick on the page and hence complete the finishes image.

2. Inkjet Printers

Inkjet printers consist of many tiny holes that drop tiny droplets of ink onto the paper. The tiny holes that include ink features in the head of the printing machine. The ink that is in the tiny holes consists of colored dye or liquid pigmented suspension. The head of the printer moves horizontally while the paper passes through the machine perpendicularly, while this step takes place, individual ink holes activate and start to drop a small amount of ink on the paper. You may find ink-jet printers very advantageous when it comes to printing out high-quality items. The technical process ensures the quality and high speed of high-quality prints.

3. Solid Ink Printers

You may have never heard about this printer, but this type of printer made a comeback in the mid-’80s and had been around till today. Inkjet printers first came out in 1986 after its development in Tektronix, which is a company based in Oregon. This type of printer includes solid sticks of ink, which is somewhat like wax. When you start the printing process, the ink melts onto a large metallic roller, which gradually gets transferred onto the page. These printers leave you with a pigmented high-quality Image and give you a pop of vibrant colors. If you touch the print, you will feel a waxy texture due to the ink sticks. These inks are long-lasting compares to the ones in inkjet printers and give a more refined touch to the printing material.

Where to Print

Now that you know the basic printing process and how it really works, you can now decide on what type of printable image you want and can decide for yourself on how you wanted it printed out. You can contact Automation Graphics, as they have the best printing services and will help you out to achieve high-quality prints